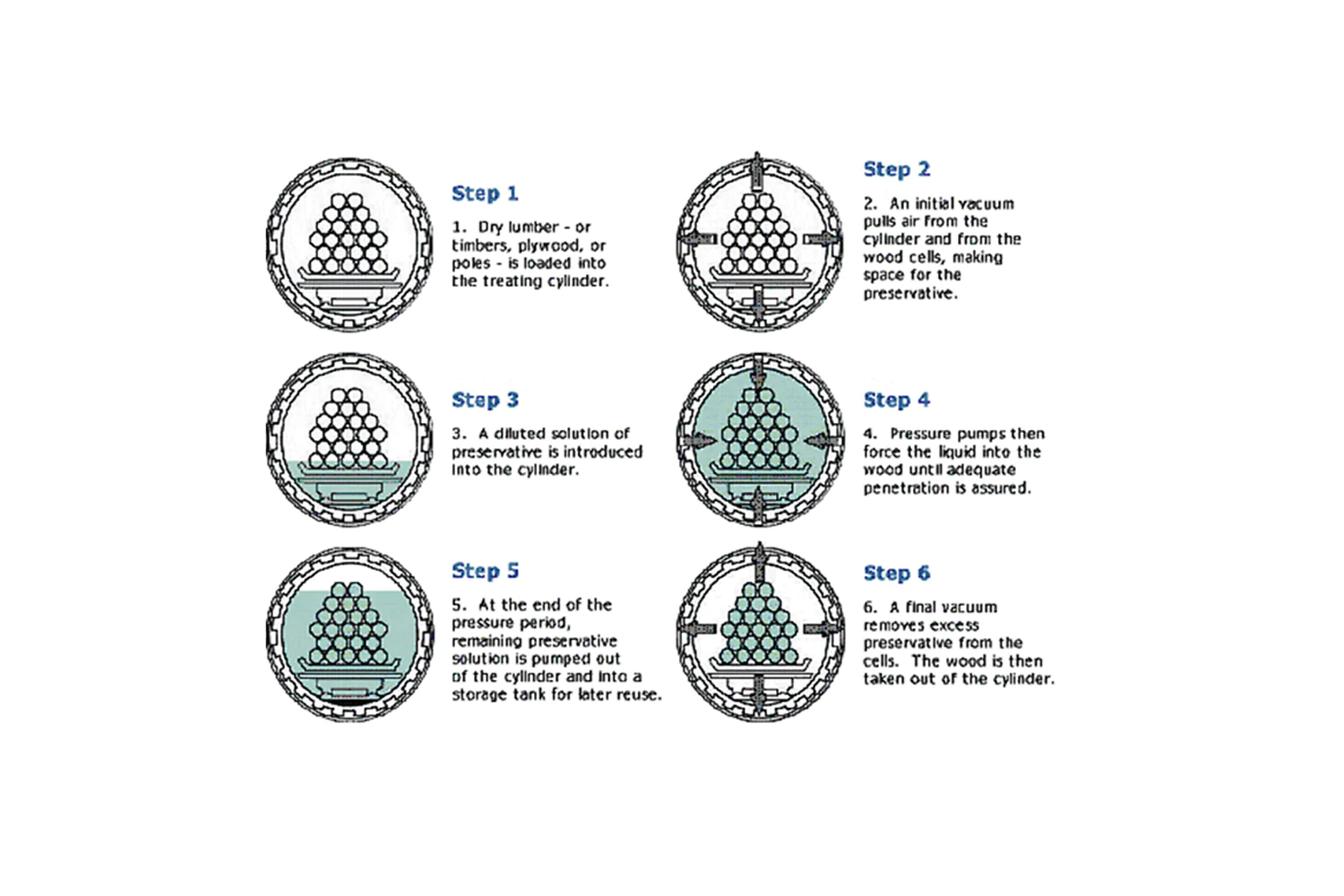

Pressure treatment is essentially the process of impregnating timber with a chemical preservative designed to protect the timber against fungal attack, rot and decay. These preservatives can be categorised into three broad groups: water-borne, oil borne and light organic solvent, however the application process is generally the same for each as outlined in the diagram below:

Timber treatments

Most softwood timber products should be supplied pressure-treated to give the product the longest possible ‘in service’ life, but what does this mean?

What is pressure treatment?

Use classes

Pressure treated timbers are split into several different ‘classes’ which are created by using a different solution strength during the treatment cycle. It is important to make sure you pick the correct class for your specific requirements to ensure long lasting performance. As a very brief overview the main classes are:

| Class type | Class description |

|---|---|

| Use Class 1 | Internal timbers that will permanently be dry |

| Use Class 2 | Class description |

| Use Class 3 | External timbers used above ground and exposed to the weather |

| Use Class 4 | External timbers in direct contact with the ground and/or fresh water |

Depending on the class you select you will have a different projected ‘in service life’, this basically means the expected life-span of the timber if it is installed correctly. For example, most decking will be treated to Use Class 3 and come with a 15-year in-service-life.

Colour

Pressure treatment will generally leave the timber with a green or brown colouring depending on the specific chemical being applied, however over time the timber with weather to a silver/grey appearance regardless of its original colouring or treatment. This means that any timber used, regardless of whether you use multiple treatment systems will eventually be indistinguishable.

End grain preservative

The chemical preservative will only penetrate the top layers of the timber, meaning there is a section in the centre of any board that won’t be impregnated. This is absolutely fine if you are installing the timber without any cutting or drilling, however if you do intend to break the treated timber it is essential to apply an end grain preservative to keep the treatment ‘sealed’.

Environmental impact

The chemical compounds used in pressure treated timber are constantly being developed to ensure they are safe for both the users and the environment around them.

References:

https://www.selwood.com/climbing-frames/why-not-pine.html

http://www.tanalisedtimber.co.uk/using-tanalised-timber/use-class-information

https://en.wikipedia.org/wiki/Wood_preservation

Get in touch

If you have any questions or would like more information, get in touch with one of our friendly team.