Bamboo is one of the fastest growing, renewable resources in the world. It absorbs CO2 in large quantities. With its properties comparable to hardwood, Moso bamboo is the ideal alternative to increasingly scarce tropical hardwoods. Below we will explain why MOSO® is the most sustainable choice in every phase of its life cycle.

The Sustainability of MOSO® Bamboo

The Fastest Growing Hardwood Alternative

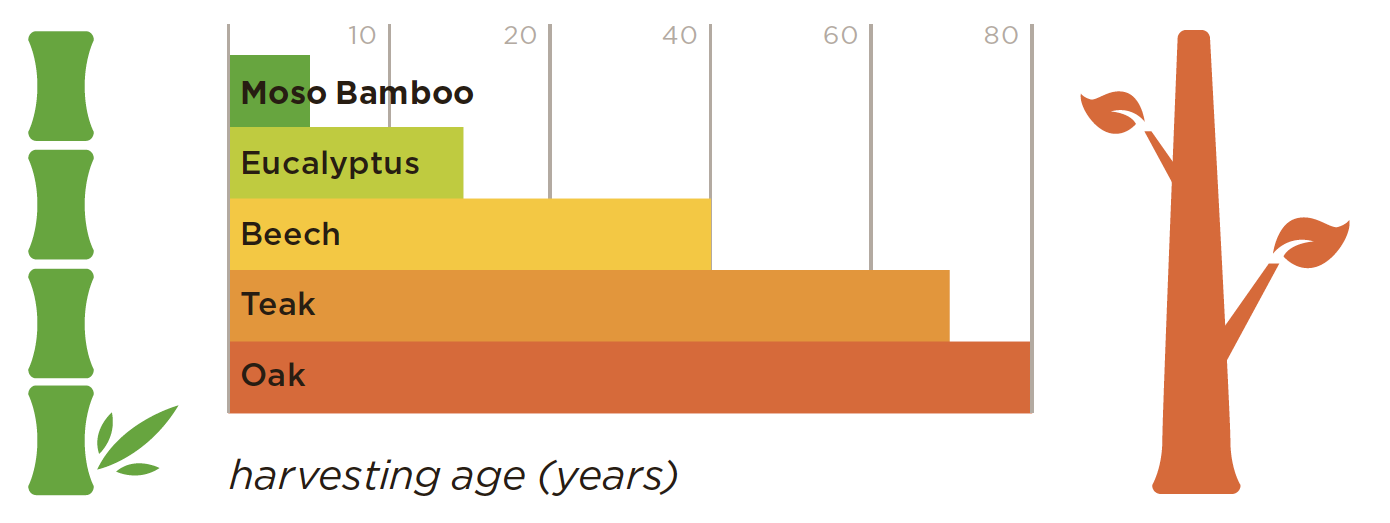

The giant bamboo species MOSO® belongs to the fastest growing plants in the world. It reaches its final length of up to 20 meters within a couple of months (with a speed of up to 1 meter a day during the growing season!). It takes the stem around 4-5 years to mature and acquire its excellent hardwood like characteristics (hardness, strength, dimensional stability). This stands in clear contrast with tropical hardwoods. These take over 50 years to mature, are increasingly scarce and often more expensive.

MOSO® Bamboo X-treme®:

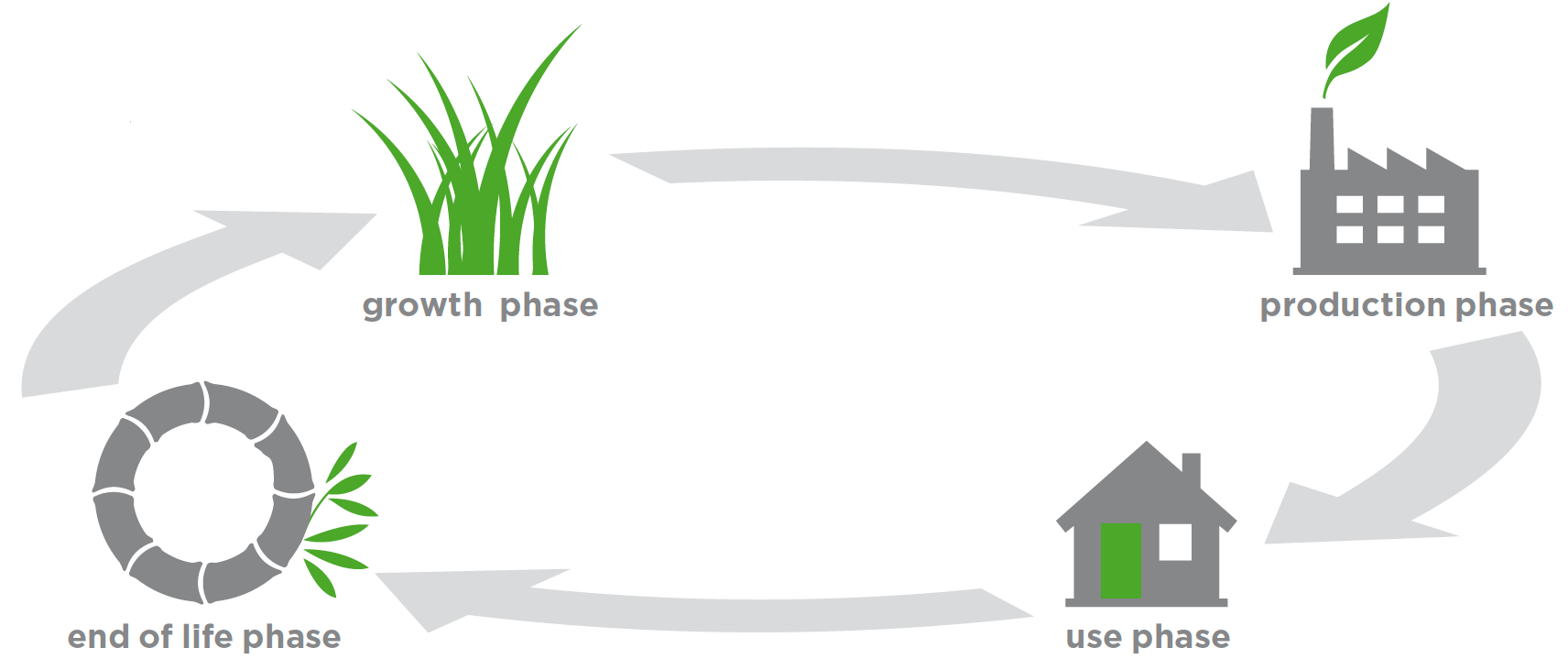

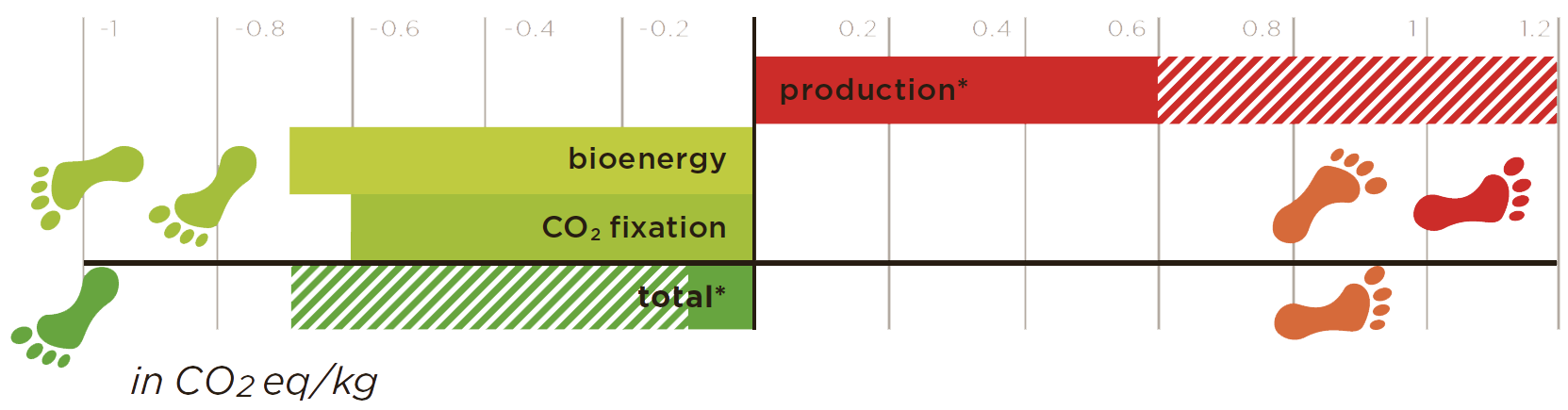

CO2 Neutral During the Product Lifespan*

MOSO® has conducted an LCA and carbon footprint study together with Delft University of Technology (TU Delft) and INBAR. The report concludes that all assessed MOSO® Products (all solid bamboo flooring, decking, beams, panels and veneer) are CO2 negative during the product lifespan (“cradle till grave”). In this result the high growth rate of MOSO® bamboo has not even been taken into account, and can be perceived as additional environmental benefit. The environmental impact of MOSO® Products, excluding carbon sequestration effect, was also published in an official Environmental Product Declaration (EPD) following EN 15804.

* This includes the CO2 (biogenic carbon – EN 16449) stored in the product.

Unsurpassed Growing Speed

Bamboo: the fastest growing plant in the world

Because of the fast growth, MOSO® bamboo is managed as an agricultural crop: the annual harvest of the 4 to 5-year-old stems – compared to 60-80 years for tropical hardwood! – provides a steady annual income to farmers and stimulates the bamboo plant to reproduce even faster. Therefore, by default, no deforestation occurs with production of MOSO® Bamboo X-treme®, while large amounts of CO2 are captured in the bamboo forests and products.

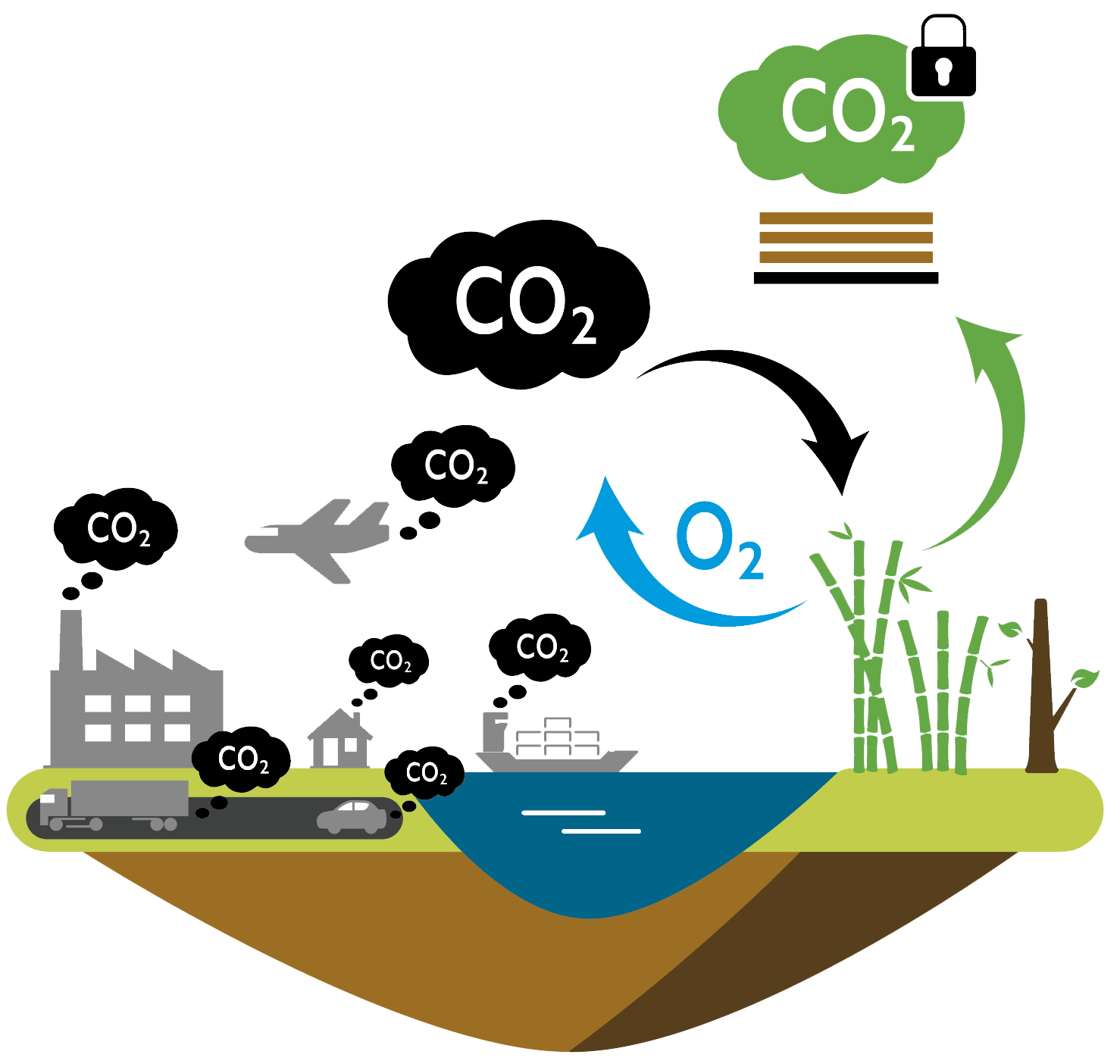

Carbon Storage in Bamboo

Biobased materials act as CO2 sinks

Through photosynthesis, plants absorb carbon dioxide (CO2) and convert it into glucose (building block for biomass) and oxygen. The CO2 is stored in the material for the lifetime of the product, and even longer if the product is recycled into new, durable products. Due to the fast growth – and related high yields – MOSO® bamboo locks far more CO2 in durable products compared to wood species.

The locked amount of CO2 can be calculated rather simply by looking at the density of the material and taking into account the biobased content. For example, Bamboo X-treme® locks almost 1.660 kg CO2 per m3 of bamboo, which is the equivalent of the CO2 emissions of 14.000 km driven by a mid-range car.

Suitable for Reforestation

MOSO® bamboo plants have an underground root system called rhizomes from which the stems grow. One single rhizome connects multiple stems. The underground system helps to hold soil and restore water tables, making bamboo very suitable for reforestation on poor grounds.

In general, 20-25% of the poles can be sustainably harvested annually without decreasing the size of the plantation or the number of poles per hectare in the forest. The rhizome does not die after harvesting. On the contrary, by harvesting the mature poles, the yield and quality of the plantation actually increases.

FSC® Bamboo Certification

FSC® is the leading certification scheme for responsible forestry. It was created to prevent the continuous depletion of forests. Although as being a giant grass with an annual thinning scheme, depletion of forests is not an issue for bamboo, in many building projects bamboo is requested with FSC® certification nonetheless. Bamboo has been included in the FSC® system since 2008 being one of the first bamboo companies to be certified and most products can be supplied with an FSC®-certification.

Easy to recycle

Of course we hope you can enjoy the MOSO® product for many years, but there will be a moment when it has ended its life cycle. At that moment another characteristic of bamboo will become important: it is easily recycled, for example as resource to make chipboard. Alternatively, it can be burnt in a biomass energy plant to create green electricity. In this way the use of fossil fuels is reduced.

The Future: 100% Cradle to Cradle Compliant Bamboo

One of the key benefits of bamboo is the rapid renewability, with stems growing to maturity within 5 years. To put this into practice and understand this benefit even more, MOSO® gives a 25 years warranty on Bamboo X-treme® for outdoor applications. During the warranty period, the bamboo has already grown back 5 times. It is clear that MOSO®’s industrial bamboo products, made from 90-98%* of sustainably sourced bamboo material from the fastest growing plant on earth, is therefore a natural fit with the biocycle of the Cradle to Cradle (C2C) concept. MOSO® is actively working in collaboration with leading glue manufacturers to develop a bio-based adhesive to bind the bamboo strips.

*depending on the product.